The Manufacturing and Anti-Corrosion Process of 3-Legged Angle Steel Towers

In the world of telecommunications infrastructure, the three-legged angle steel tower stands as a testament to robust engineering and timeless reliability. While its design may seem straightforward, the journey from raw steel to a galvanized sentinel capable of weathering decades of harsh elements is a precise and fascinating scientific process. This blog post pulls back the curtain on the complete manufacturing and anti-corrosion workflow that ensures these towers stand tall and strong.

Part 1: The Manufacturing Process – Forging the Backbone

The transformation of raw materials into a structural tower is a symphony of heavy fabrication and meticulous quality control.

1. Material Preparation & Cutting:

The process begins with high-quality low-carbon steel coils. These are uncoiled and leveled before being slit into narrow strips. These strips are then fed through a series of rolls in a cold-forming process to shape them into the standard L-shaped angle profiles. This cold-working increases the strength of the steel through strain hardening.

The long angles are then cut to specific lengths as per the tower design drawings using high-precision saw cutting or shearing. This ensures clean, burr-free ends with exact angles for perfect fit-up during assembly.

2. Punching & Drilling:

This is a critical step for the tower's bolted connection philosophy. The cut angles are moved to massive CNC (Computer Numerical Control) punching machines. These machines use hydraulic rams and custom dies to punch out the exact pattern of holes for bolts with incredible speed and accuracy. CNC technology ensures that every component is identical, eliminating assembly errors and ensuring structural integrity. Hole edges are deburred to prevent stress concentrations and ensure smooth bolt insertion.

3. Cold Bending & Forming:

For certain components like bracings or curved connections, angles need to be bent. Cold bending is predominantly used, where the steel is formed at room temperature using hydraulic presses or rotary draw benders. It's efficient and preserves the material's properties. For very thick sections or tight radii, hot bending (heating the steel to a specific temperature to make it pliable) might be employed, though it's less common for standard angles.

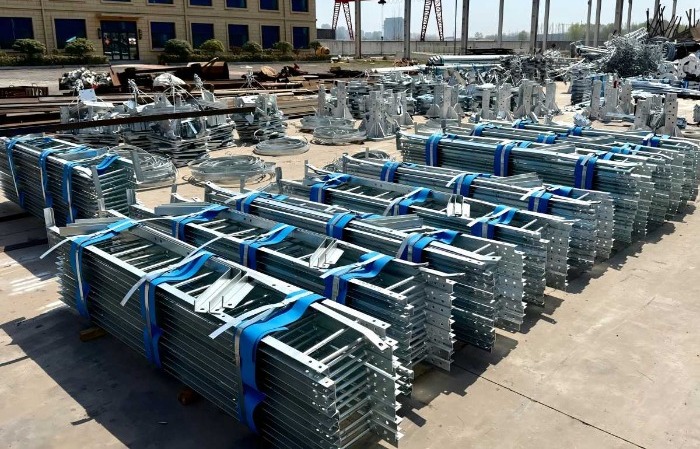

4. Assembly & Welding (Sub-Assembly):

While the primary structure is bolted for ease of transport and field assembly, smaller sub-assemblies like connection plates, stub ends, and ladder supports are welded. Skilled welders use processes like SMAW (Shielded Metal Arc Welding) or more efficient FCAW (Flux-Cored Arc Welding). All welding is performed to strict procedures, and welds are visually inspected and often tested using Non-Destructive Testing (NDT) methods like Magnetic Particle Inspection (MPI) to ensure they are free of cracks and defects.

Part 2: The Crown Jewel of Corrosion Protection: Hot-Dip Galvanizing

After fabrication, every single component undergoes the most crucial step: hot-dip galvanizing. This process provides a metallurgical bond between zinc and steel, offering superior, long-lasting protection.

The Galvanizing (Process Flow):

-

Degreasing/Caustic Cleaning: Removes organic contaminants like oil, grease, and dirt.

-

Pickling (Acid Bath): Immersion in a diluted Hydrochloric or Sulphuric acid solution to remove mill scale and rust, exposing perfectly clean steel.

-

Fluxing: The components are dipped in a zinc ammonium chloride solution. This flux prevents oxidation before galvanizing and promotes the zinc-steel reaction.

-

Galvanizing: The dried components are immersed in a bath of molten zinc at around 450°C (840°F). The iron in the steel reacts with the zinc to form a series of zinc-iron alloy layers, topped by a layer of pure zinc.

-

Quenching: The galvanized parts are slowly withdrawn from the bath and then cooled in a water quench tank to stop the reaction and solidify the coating.

Zinc Thickness Control & Quality Inspection:

-

Thickness: Standards like ASTM A123 specify minimum coating thicknesses based on material thickness. A typical angle will have an average coating of 85-100 µm (3.5-4 mils). Thickness is verified using magnetic or electromagnetic gauges.

-

Quality: The coating is inspected for uniformity, smoothness, and adhesion. Key tests include the "Preece Test" (copper sulphate dip) for the presence of uncoated spots and a "Quench Test" to check for excessive brittleness.

Part 3: Application & Economics: Choosing the Right Protection

While hot-dip galvanizing is the industry standard for a reason, other options exist for specific scenarios. The choice is a balance of environment and lifecycle cost.

| Corrosion Environment | Recommended Protection | Technical Rationale | Lifecycle Cost Analysis |

|---|---|---|---|

| Inland / Rural (C1-C2) | Hot-Dip Galvanizing (HDG) | Provides cathodic protection (sacrifices itself to protect the steel) and a robust barrier. Low maintenance. | Lowest LCC. High initial cost is offset by 40-50+ years of service with zero maintenance. The benchmark for value. |

| Coastal / High Humidity (C3-C4) | HDG or HDG + Duplex System | Salt and moisture drastically accelerate corrosion. A Duplex System (HDG followed by a specialized paint) provides enhanced barrier protection and extends service life significantly. | HDG alone: Good, may require inspection/repaint later. Duplex System: Higher initial cost but can extend the maintenance-free period by 1.5-2x, offering excellent long-term value. |

| Severe Industrial (C4-C5) | Duplex System or Specialty Coatings | Chemical pollutants (SO₂, NOx) create highly aggressive acids. A thick, chemical-resistant paint layer over the galvanizing is essential. | Highest initial cost but the only economically viable long-term solution. Prevents catastrophic failure and constant repairs. |

| Special Cases (Aesthetics, Touch-up) | Paint/Spray Systems (alone) | Used only for visual blending in urban areas or for on-site repair of galvanized coating damaged during transport/installation. | High LCC. Used only where HDG is not feasible. Requires frequent inspection and recoat cycles (every 5-15 years). |

Conclusion: An Investment in Longevity

The manufacturing and galvanizing of a three-legged angle steel tower is not merely a production line; it's a commitment to quality and longevity. The upfront investment in rigorous fabrication and superior hot-dip galvanizing pays massive dividends over the tower's entire lifecycle, minimizing downtime, eliminating expensive maintenance climbs, and ensuring network reliability for generations. When specifying your next tower project, understanding this process is key to making a smart, technically sound, and ultimately economical decision.

Learn more at www.alttower.com